Multiple Object Detection and Segmentation for Automated Removal in Additive Manufacturing with Service Robots

Abstract

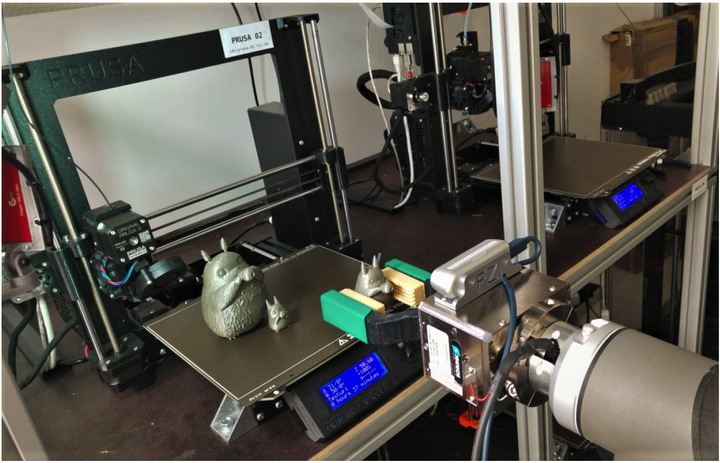

3D printing is nowadays getting more important in industrial production plants, especially in low quantity productions. Currently, almost no printer model for fused lament fabrication (FFF) has the capability to start a new print automatically after the present one is nished. While the printed object is still on the build plate, the printer cannot continue and this is noneconomical. Manual work is required to be able to start a consecutive job. To get one step closer to full automation of the 3D printing process, the removal process should be automated process, for example with robots. This approach presents a method to determine the number, positions and sizes of all printed objects by analyzing the G-code le of the current print job. It is determined wether the objects can be removed by a robotic arm and in which order. Furthermore, a depth camera is used to verify the hypothesis right after the print process is done. The additional veri cation is necessary to detect possible changes in the printed structures due to errors during the printing process. In the last step the objects are automatically removed by a robot from the build plate.